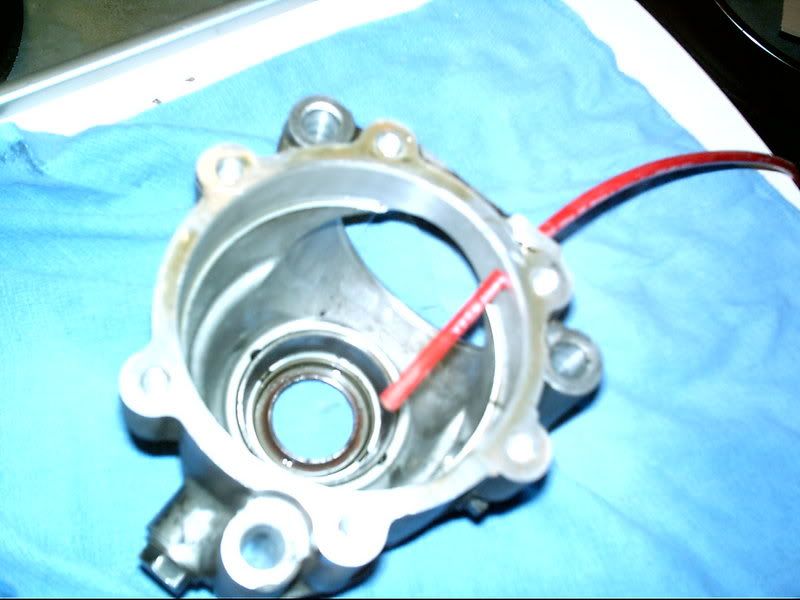

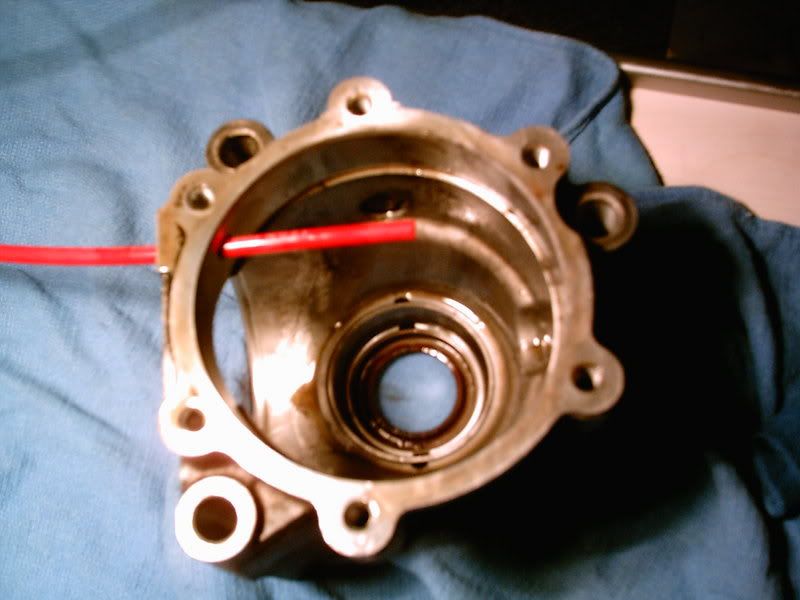

I find it odd that the weakest link on my car is also the part that was designed by German engineers. These pictures are of a 1993 25 spine T/C. It is the portion of the T/C that houses the gears. It is the portion that most frequently breaks. It is no wonder it breaks. At the weakest portion of the housing the genius engineers drilled a hole through the housing. Note the red wire I have put through the hole. It is not surprising that this is the area that most T/C crack from.  I'm hoping that the T/C will be produced in cast iron or CNC'd out of steel. I really don't see how this aluminum T/C case holds up as well as it does.

I'm hoping that the T/C will be produced in cast iron or CNC'd out of steel. I really don't see how this aluminum T/C case holds up as well as it does.

![Image]()

![Image]()

![Image]()